|

|

Development Background |

|

| |

|

|

| |

Development Background |

|

| |

|

|

| |

The graphic control software seldom provides overall system integration, and the data resource

sharing among levels is The graphic control software seldom provides overall system integration, and the data resource

sharing among levels is

difficult, or even impossible. |

The integrators often need to design systems using the equipment SDK, connect I/O to database

through various The integrators often need to design systems using the equipment SDK, connect I/O to database

through various

standards, thus increase the project cost and reduce the working efficiency. |

Smart 4 provides overall integration for all levels to reduce the development time, so that

the system integrators can Smart 4 provides overall integration for all levels to reduce the development time, so that

the system integrators can

focus on the expert field (such as air conditioning, sewage

treatment, etc.) to enhance the trust from the customers. |

| |

|

|

| |

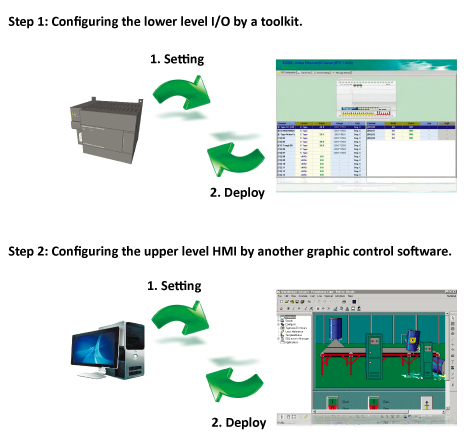

Traditional graphic control system with I/O modules Traditional graphic control system with I/O modules |

|

| |

|

|

| |

|

|

| |

Smart 4 system design and operating with I/O modules Smart 4 system design and operating with I/O modules |

|

| |

|

|

| |

|

|

| |

|

|

| |

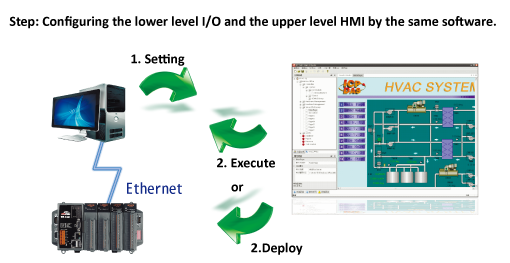

The hardware and software of different levels are constituted from different vendors, so the

function coordination among equipments is difficult. The hardware and software of different levels are constituted from different vendors, so the

function coordination among equipments is difficult. |

Using the inadequate SDK functions, the integrators cannot perform the system optimum. Using the inadequate SDK functions, the integrators cannot perform the system optimum. |

The overall functions may be acceptable in checking step, but the following system

performance, reliability and safety The overall functions may be acceptable in checking step, but the following system

performance, reliability and safety

are very poor. |

| |

|

|

| |

The difference of peripheral Integration between Smart 4 (right) and general software (left) The difference of peripheral Integration between Smart 4 (right) and general software (left) |

|

| |

|

|

| |

|

|

| |

The overall system integration and the customers add-on requirements (such as data calculation

and analysis) make The overall system integration and the customers add-on requirements (such as data calculation

and analysis) make

design more difficult, so the integrator cannot satisfy the customers, the

system just keep to monitor equipments, do

not provide full auto control functions. |

| |

|

|

| |

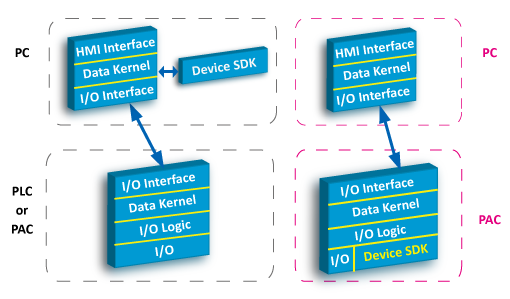

The traditional software working with PLC or I/O devices The traditional software working with PLC or I/O devices |

|

| |

|

|

| |

|

|

| |

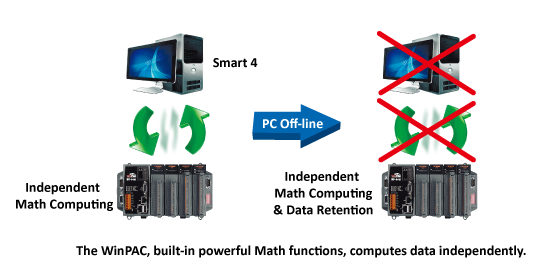

Smart 4 working with WinPAC Smart 4 working with WinPAC |

|

| |

|

|

| |

|

|

| |

The integration of the traditional control system is poor, the user-interface is not friendly,

such as, to retrieve or query a The integration of the traditional control system is poor, the user-interface is not friendly,

such as, to retrieve or query a

record may need to run several programs, hard in access

operating, and cause configuring error often (below).

|

Smart 4 is the I/O control system of environmental devices, the personnel access control system,

and the monitoring Smart 4 is the I/O control system of environmental devices, the personnel access control system,

and the monitoring

system. Users can retrieve the queried card number, machine, personnel data

and image record via an easy user-

interface using the same software. Smart 4 simplify the

operating process, combine various authorize management,

and reduce the probability of

operating errors. |

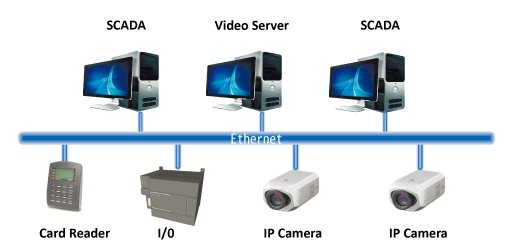

| Compare the traditional software with Smart 4 in querying personnel access record and video data

as below. |

| |

|

|

| |

The querying process for the personnel access record/video in traditional software The querying process for the personnel access record/video in traditional software |

|

| |

|

|

| |

Step 1. Query a specific card number and access time in the access control software of

the

SCADA server.

|

Step 2. Retrieve a specific time video via the access time and screen copy to files in

the video

software of the Video server. |

| Step 3. Compare the video files with the staff image record that queried by the card

number in the personnel database of the personnel database server. |

| With the complex process and the two-tier structure, once the server computers are

offline, the entire system will useless. |

| |

|

|

| |

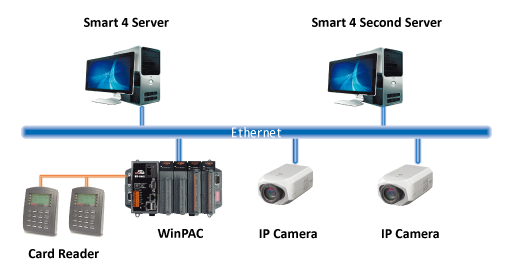

Smart 4 querying process for the personnel access record/video Smart 4 querying process for the personnel access record/video |

|

| |

|

|

| |

All the steps are processed in the Smart 4 Server. Query a specific time/person access data

in the historical events window, and also display the corresponding video record and the

personnel basic data.

|

| |

| If Smart 4 Server is offline, the card readers can still work, and can copy/query the video

record from the Smart 4 Second Server. |

|

|

| |

|

|

| |

The Smart 4 system was customized according to the demand at that time, no future expanding

planning. After one year The Smart 4 system was customized according to the demand at that time, no future expanding

planning. After one year

warranty, when customers want to expand I/O points or new functions,

they often need to build a new system, or to

destroy the original structure that always leads

to a system architecture collapse.

|

| |

| Based on above, Smart System upgrades with the principles of economic, performance, value

and convenience to launch the grand new version "Smart 4". |

|

|

| |

|

|

| |

Conclusion: |

|

| |

Smart 4 gives a new thinking for system development, designs functions in users view, frames the system core on ten years of integration experience, provides an easy-to-use, reliable and overall designing solution for system integrators developing the environmental control systems, and achieves the win-win goal of the end-users, system integrators and equipment manufacturers.

|

|

|

| |

|

|

|